The following is a guest blog from Kristin Osborne, Communications Manager at Paul G. Allen School of Computer Science & Engineering, at the University of Washington (UW) and CCC Council member Shwetak Patel, Washington Research Foundation Entrepreneurship Endowed Professor in Computer Science and Engineering and Electrical Engineering, at UW. At the Computing Community Consortium (CCC) we know that everyone is dealing with a lot in these unprecedented times. We are continuing to work on behalf of the computing research community to catalyze research, but we also want to provide ways to help the community. This blog is from a series of posts about ways computing researchers are using computing to adapt and help in these times. We hope you find something that may help you, either now or in the future.

Global Innovation Exchange

Shortages of personal protective equipment (PPE) such as masks, face shields, and other items for medical personnel are well-documented in multiple communities responding to the current pandemic. Without this critical equipment, individuals who are caring for COVID-19 patients risk contracting the disease themselves and/or passing it on to others.

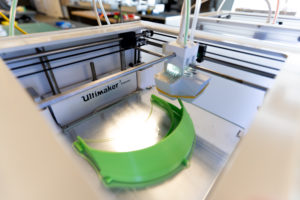

Recently, UW Medicine launched an effort to harness the University of Washington’s extensive network of maker spaces and fabrication expertise to address the shortage of PPE. As part of a campus-wide initiative, a group of faculty, staff and students who specialize in fabrication techniques at the Paul G. Allen School of Computer Science & Engineering, Department of Mechanical Engineering, and the UW Center for Research in Education and Simulation Technologies (CREST) have been working alongside UW Medicine clinicians and other partners to rapidly design, fabricate, and test safe and effective PPE that can be locally produced and put it in the hands of front-line health care workers.

The team has focused on streamlining the production process across various fabrication labs, material sources, and newly created assembly stations across the Seattle campus and in the surrounding community. These include a collection of student maker spaces in a partnership between the College of Engineering and Department Housing & Food Services; facilities at the Global Innovation Exchange (GIX), a partnership between UW and Tsinghua University, located across Lake Washington in Bellevue; and maker spaces managed by roughly a dozen academic departments. This approach will enable the network to quickly ramp up production as new designs are approved.

Global Innovation Exchange

In late March, the team commenced production of its first project — a face shield designed in collaboration with the Redmond, Washington-based firm Design that Matters — after UW Medicine obtained design approval from the National Institutes of Health (NIH). As far as the team is aware, its face shield is one of or possibly the only DIY design recommended by the NIH for use in clinical settings. The team has so far produced over 1,000 face shields. The consortium of clinicians, computer scientists, engineers, designers, and makers is also exploring design and fabrication of additional equipment, such as gowns, reusable respirator masks, and aerosol boxes, to aid in the pandemic response.

Learn more about how Paul G. Allen School researchers are responding to COVID-19 here.